Unique Advantages of Aluminum Nitride Ceramics

Compared to conventional alumina (Al₂O₃) ceramics, aluminum nitride (AlN) ceramics offer the following distinctive advantages:

The most significant advantage of AlN is its extremely high thermal conductivity, with a theoretical value reaching 320 W/(m·K), which is 5–10 times that of alumina. This means that under the same operating conditions, AlN ceramics can withstand higher heat flux densities. As a packaging substrate or casing, AlN ceramics are particularly beneficial for heat dissipation in high-power chips or modules. When fabricated into AlN metal-ceramic heating elements (AlN Ceramic Heaters), they enable rapid heating. When made into electrostatic chucks (Electro-Static Chucks), they allow for quick preheating/heating of adsorbed wafers.

AlN has a low coefficient of thermal expansion (CTE) of only 4.3 ppm/K, which is close to that of silicon chips (3.5–4.0 ppm/K). This means there is a natural, high degree of thermal expansion matching between silicon chips and AlN ceramics, inherently improving packaging reliability.

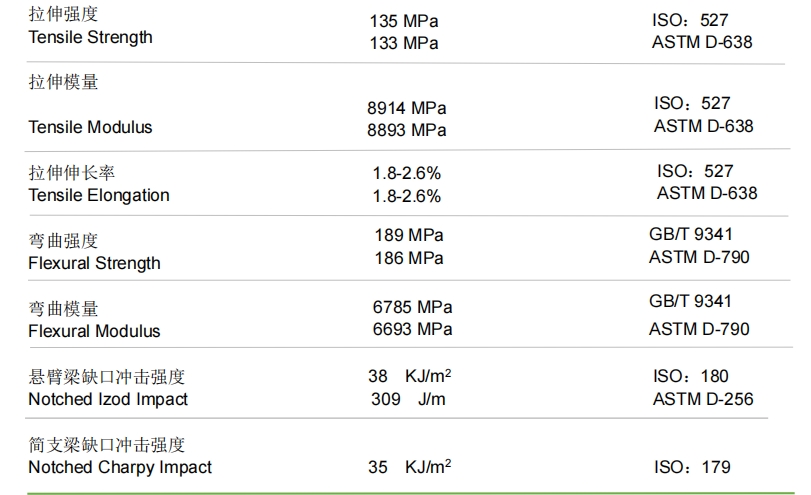

Additionally, AlN ceramics exhibit mechanical properties, electrical performance, and corrosion resistance comparable to those of alumina ceramics.

AlN ceramics combine high thermal conductivity, low thermal expansion, high strength, and chemical corrosion resistance, making them ideal heat dissipation materials, especially for applications in large-scale integrated circuits and high-performance electronic devices.

Factors Affecting the Thermal Conductivity of AlN Ceramics

Since AlN ceramics are insulating solids, the contributions of electron and photon heat transfer are negligible. Their primary heat transfer mechanism is phonon (lattice vibration) conduction. The Al-N bonds in AlN ceramics have high bond energy and short bond lengths, resulting in high phonon propagation speeds, which explains their high thermal conductivity.

Although the theoretical thermal conductivity of AlN can reach 320 W/(m·K), currently only a few companies can produce AlN ceramics with thermal conductivities of up to 230 W/(m·K). Typically, the actual thermal conductivity of commercial products ranges from 150–180 W/(m·K). The factors affecting the thermal conductivity of AlN ceramics are as follows:

From a microscopic perspective, grain boundaries, interfaces, secondary phases, defects, and phonon scattering in the crystal structure all influence phonon transmission. From practical experience, the main factors affecting the thermal conductivity of AlN ceramics include lattice density, oxygen content, raw powder purity, and microstructure.

1、Density

Samples with low density contain numerous pores, which scatter phonons and reduce their mean free path, thereby lowering the thermal conductivity of AlN ceramics. Additionally, low-density samples may fail to meet the mechanical performance requirements for certain applications.

2、Oxygen Content

Due to the strong affinity between AlN and oxygen, the surface of AlN readily oxidizes when exposed to air or moisture, forming an alumina film. This introduces aluminum vacancies and oxygen defects, which can diffuse into the AlN lattice during sintering. Once these defects spread throughout the AlN crystal network, the mean free path of phonons is reduced, leading to a decline in thermal conductivity.

3、Lattice Defects

Research has found that the types of defects in AlN (aluminum nitride ceramic) lattices are related to oxygen atom concentration.

When the oxygen concentration is below 0.75%, oxygen atoms are uniformly dispersed in the AlN lattice, substituting nitrogen atoms and generating aluminum vacancies.

When the oxygen concentration is 0.75% or higher, the positions of aluminum atoms in the AlN lattice shift, eliminating aluminum vacancies and creating octahedral defects.

At higher oxygen concentrations, the lattice develops extended defects such as polytypes, inversion domains, and oxygen-containing stacking faults.

Measures to Improve the Thermal Conductivity of AlN Ceramics

1、Increase Density

Use fine-grained, highly sinterable micro/nano powders, incorporate sintering aids, or employ high-energy physical-assisted sintering methods to enhance the sintered density of the ceramics.

2、Reduce Oxygen Content and Internal Defects

Select high-purity, low-oxygen raw powders. Ensure that the storage of raw powders and the forming of semi-finished products avoid moisture exposure. Strictly control oxygen levels during atmosphere sintering.

About Xiamen Juci Technology

Xiamen Juci Technology is the leading AlN powder and AlN ceramics manufacture in China. Our products feature excellent thermal conductivity, electrical insulation, and mechanical strength, widely used in electronic packaging, semiconductors, LED heat dissipation, and other fields. With advanced manufacturing processes and strict quality control, we provide high-reliability AlN substrates, structural components, and tailored solutions to support advanced manufacturing industries.

Media Contact:

Xiamen Juci Technology Co., Ltd.

Phone: +86 592 7080230

Email: miki_huang@chinajuci.com

Website: www.jucialnglobal.com