Resin Manhole Cover (Composite Manhole Cover)

In fact, a resin manhole cover—also known as a polymer fiberglass manhole cover or a composite manhole cover—is a new type of manhole product. It is manufactured by high-temperature, using glass fiber and its products as reinforcing materials, and synthetic resin as the matrix material.

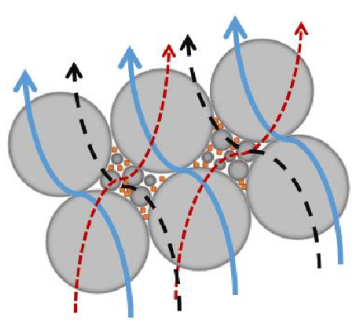

Among the added materials, fiber reinforcements play the primary role. Their main features include low density, and high specific strength and modulus. For example, materials reinforced with carbon fiber and glass fiber have specific strength and modulus several times higher than those of steel and aluminum alloys.

In addition, these materials offer excellent chemical stability, friction and wear resistance, self-lubrication, heat resistance, fatigue resistance, creep resistance, noise reduction, and electrical insulation properties.

Another characteristic of fiber-reinforced materials is anisotropy, meaning the fibers can be strategically oriented based on the strength requirements of different parts of the product. For instance, composite materials reinforced with carbon fiber can retain sufficient strength and modulus even at 500°C.

The Application and Advantages of Resin Manhole Covers

Resin manhole covers are playing an increasingly important role in our daily lives. They stand out due to their self-cleaning properties and wide range of applications.

When used on roadways, resin manhole covers offer several benefits: they are electrically insulating, noiseless, have no recyclable value, and are naturally theft-resistant—making them an irreplaceable alternative to traditional cast iron covers.

Manufactured through a unique molding process, resin manhole covers bring a fresh aesthetic to urban environments. With a typical service life of 20 to 50 years, these high-temperature-formed composite covers offer a range of advantages: lightweight yet high strength, excellent fatigue resistance, safety in case of breakage, easy molding, low noise when driven over, strong chemical and acid/alkali resistance, and a clean, attractive appearance. Additionally, they help reduce pollutants in wastewater.

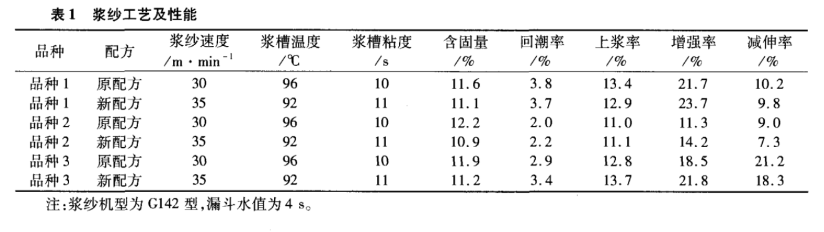

Currently, manufacturers use a variety of materials to produce composite manhole covers, but the main features are largely similar:

Excellent Anti-Theft Performance

Composite covers are generally made from unsaturated resin, fiberglass, and other materials through a specialized high-temperature one-step molding process. The finished products have no recyclable value, and even extracting the internal reinforcement (such as steel bars) is extremely difficult.

Long Service Life

By using high-performance resins, fiberglass, and special production formulas, these covers ensure deep resin penetration into the fibers, significantly enhancing the bonding strength. This prevents internal damage under cyclic loading, ensures long-term durability, and avoids common problems like poor adhesion seen in inferior products.

High/Low Temperature Resistance, Excellent Insulation, and Strong Corrosion Resistance

The product is corrosion-resistant, non-toxic, and free of metal additives. It can be used in demanding and harsh environments. Covers produced by Baisite have passed national authoritative testing, with outstanding performance in acid and alkali resistance, corrosion resistance, and anti-aging—meeting all relevant quality standards.

Attractive and Practical, Premium Appearance

Custom designs are available to meet high-end client requirements. Complex logos and multiple colors can be integrated onto a single cover, delivering detailed graphics with bright, distinct colors. The surface can also be made to simulate various stone textures and colors to match surrounding pavement.

Strong Load-Bearing Capacity

The bottom structure of the cover features a special design. The continuous reinforced fibers used are integrated with fiberglass cloth, ensuring a solid structure and providing excellent load-bearing performance.

Eco-Friendly, Anti-Slip, and Low Noise

When driven over by vehicles, the cover remains non-slip, produces no harsh noise, and causes no pollution—making it a safer and more environmentally friendly solution.